During the past 20 years. The technological advances have allowed reducing motor vehicle emissions of about 95% of carbon monoxide and hydrocarbon-free and 75% of nitrogen oxides. This is a clear example of joint development of automotive and refining industries, the first and perhaps most significant: the elimination of lead from gasoline and therefore the possibility to equip new vehicles with catalytic converters for treatment of exhaust gases with the consequent reduction in the toxicity of them. This design is completed with the addition of the oxygen sensor, enabling control and regulate the ideal amount of permanently air for combustion.

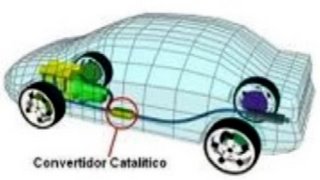

This report clearly detail how an engine pollution. Among the solutions studied worldwide to minimize the toxicity of emissions from the combustion of petrol engines have been developed: improvements in combustion chamber design and widespread use of catalytic converter system exhaust phases and Lambda probe. The term "Catalytic Converter" refers generically to a reactor installed after the exhaust manifold. It has a stainless steel housing that contains within it the "catalyst." Chemically active, supported by a ceramic hive covered with a buffer layer that protects it from shock.

This report clearly detail how an engine pollution. Among the solutions studied worldwide to minimize the toxicity of emissions from the combustion of petrol engines have been developed: improvements in combustion chamber design and widespread use of catalytic converter system exhaust phases and Lambda probe. The term "Catalytic Converter" refers generically to a reactor installed after the exhaust manifold. It has a stainless steel housing that contains within it the "catalyst." Chemically active, supported by a ceramic hive covered with a buffer layer that protects it from shock.

This hive is made up of thousands of tiny channels (cells) through which pass the exhaust gases. The walls of these channels generate a contact area equal to three football fields. The formulation includes a number of active substances such as aluminum oxides, noble metals (catalytically active): Platinum, Rhodium, Palladium, and promoters or specific retardants, which increase or retard the catalytic action of the above, on certain reactions. Recall that we exhaust gases as pollutants, primarily three classes of compounds: carbon monoxide, nitrogen oxides and unburned hydrocarbons. The mechanism of action of three-way catalytic converter, so called because it acts primarily by removing these three pollutants in the same compartment, through oxidation and reduction reactions, transforms them into non-toxic compounds: Nitrogen, Water and Carbon Dioxide .

What is the catalytic converter? How it works

Today there are millions of gasoline vehicles circulating in the world and each is a source contamination. In large cities such as pollution from these vehicles can cause serious problems. To solve this problem the governments of some countries have established laws that limit the amount of pollutants that a car can generate, forcing the auto industry to find ways to make more efficient and cleaner engines. However, more efficient than a petrol engine is always generates a lot of pollutants, this is precisely what motivated the use of catalytic converter since it is a system that treats the engine exhaust gases before letting them free in the atmosphere .

Pollutants from gasoline engines

Modern vehicles carefully control the amount of fuel burned to reduce pollutants. computers maintain a vehicle air-fuel ratio very close to the stoichiometric ratio is the ideal relationship between them. Theoretically, if the relationship is exact and pure gasoline is all the fuel would be used to generate power, discarding only carbon dioxide and water.

The main emissions of a gasoline engine are:

Nitrogen (N2): 78% of air is nitrogen and this only happens on the inside of the engine without being altered.

carbon dioxide (CO2): This is a product of combustion. The gas carbon reacts with oxygen in the air.

Water vapor (H2O): Water is also a product of combustion. Hydrogen gas reacts with oxygen in the air to form water.

These emissions are not considered as contaminants even if the global warming of the earth is attributed in part to emissions of carbon dioxide.

all know that the process combustion within our engines is not ideal since fuel has certain impurities and is impossible to maintain an accurate air-fuel all the time. This causes the emission of these pollutants:

Carbon monoxide (CO) gas is a colorless, odorless poison that is generated by incomplete combustion.

Hydrocarbons (HC): Mainly residues unburned fuel inside the engine.

nitrogen oxides (NOX): It may be carbon monoxide or nitrogen dioxide. Is the cause of acid rain.

These are the three key pollutants a catalytic converter must be reduced.

reduces contaminants How a catalytic converter?

Modern vehicles are equipped with catalytic converters three-way referring to the three pollutants should be reduced (CO, HC and NOx). The converter uses two types of catalysts, a reduction and one oxidation. Both consist of a ceramic structure coated with metal usually platinum, rhodium and palladium. The idea is to create a structure that exposes the maximum surface of the catalyst against the flow of exhaust gases, also minimizing the amount of catalyst required because it is very expensive.

Reduction catalyst

The reduction catalyst is the first step of the catalytic converter. uses platinum and rhodium to reduce NOx emissions. When a molecule of carbon monoxide or nitrogen dioxide comes into contact with the catalyst, the nitrogen atom traps and releases oxygen, nitrogen atom then joins with another nitrogen atom and released. That is, breaks down the nitrogen oxides in oxygen and nitrogen which are the components of air and therefore are environmentally friendly.

Oxidation Catalyst

The oxidation catalyst is the second stage of the catalytic converter. This platinum and palladium catalyst for making hydrocarbons (HC) and carbon monoxide (CO) leaving the engine and reacted with oxygen engine is also generating carbon dioxide (CO2).

control system

A third step that monitors the engine's exhaust gases and uses this information to control fuel injection system engine. It has an oxygen sensor in the exhaust gases motor before reaching the catalytic converter. This sensor informs the computer about the amount of oxygen in the exhaust, with this information the computer can increase or decrease the amount of oxygen in the exhaust by adjusting the air-fuel ratio. The control system allows the computer to make sure the engine is running a very close to the stoichiometric and also allows you to keep enough oxygen in the exhaust to oxidize hydrocarbons and carbon monoxide.

This is a contribution of http://www.lubrimax.com.mx/recipes.ihtml?s=2&menvar=26

Pablo Ramírez Torrejón (PD)

0 comments:

Post a Comment